Explosive beginnings

Le véhicule de chargement/déchargement des lanceurs Hawk. © U.S.Army.

Le véhicule de chargement/déchargement des lanceurs Hawk. © U.S.Army.

Loading of a Hawk launcher. © U.S.Army.

September 1988. I'm twenty years old and I have just passed the tough BCO training at the Air Defense Artillery School of

Lombardsijde. After several hours of an exhausting journey by train and bus, I arrived at Essentho (Nordrhein-Westfalen), home

of the 62nd Hawk missiles battalion. The place is downright lugubrious; the barracks are positioned on a wet plateau beaten by

the wind.

Moreover, I learn that I'm at the wrong address. I was assigned to the Alpha battery, which has its own quarters in the town of

Korbach, still farther east. I spent the last thirty kilometers in the back of a supply truck, chilled in my nice dress uniform.

The reception at Korbach was much better. My three fellow officers were special guys who welcome me warmly. I had a comfortable

room and spent the evening discovering the charming town with my fire team. My Battery Control Assistant (BCA) was not only the

unit’s most experienced officer, but also a veteran who knew his way around in all the local taverns...

MIM-23B "Improved Hawk". © Collection M.Wyffels.

After this memorable night, the first few weeks were spent on completing my training. I discovered with dismay that I still had

much to learn. My room was littered with technical manuals and I spent the evenings in a shielded room to learn the secrets of

the 2.ATAF procedures (2nd Allied Tactical Air Force). A month later, I was finally cleared for my first duty period on the

missile site at Flechtdorf.

The day had just begun when a sergeant asked me to direct the unloading of missiles as security officer (OS). I had no idea of

what to do. Fortunately, the role of the OS was normally limited to be present. My men were experts and knew very well what to

do, but an officer had to be present because ‘that's the rule’. The loading/unloading was done with a tracked vehicle with

three arms to move the missiles from transport pallets to the launchers and vice versa. I was watching the operation and did

my best to not interfere and especially to avoid to be crushed... The driver extended the articulated arms over the missiles

and two soldiers unlocked one missile from the launcher under the eyes of an experienced sergeant technician. The operator then

activated a joystick to operate the arms in order to move the missile. Suddenly, the driver screamed, jumped from the vehicle

and ran away, together with the rest of the team. They dove into a trench twenty yards away while I remained standing alone

beside the missiles.

MIM-23B "Improved Hawk". © Collection M.Wyffels.

After this memorable night, the first few weeks were spent on completing my training. I discovered with dismay that I still had

much to learn. My room was littered with technical manuals and I spent the evenings in a shielded room to learn the secrets of

the 2.ATAF procedures (2nd Allied Tactical Air Force). A month later, I was finally cleared for my first duty period on the

missile site at Flechtdorf.

The day had just begun when a sergeant asked me to direct the unloading of missiles as security officer (OS). I had no idea of

what to do. Fortunately, the role of the OS was normally limited to be present. My men were experts and knew very well what to

do, but an officer had to be present because ‘that's the rule’. The loading/unloading was done with a tracked vehicle with

three arms to move the missiles from transport pallets to the launchers and vice versa. I was watching the operation and did

my best to not interfere and especially to avoid to be crushed... The driver extended the articulated arms over the missiles

and two soldiers unlocked one missile from the launcher under the eyes of an experienced sergeant technician. The operator then

activated a joystick to operate the arms in order to move the missile. Suddenly, the driver screamed, jumped from the vehicle

and ran away, together with the rest of the team. They dove into a trench twenty yards away while I remained standing alone

beside the missiles.

Operational Readiness Evaluation

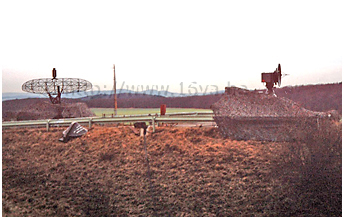

Les radars devaient tourner de concert avec une grande précision. Ici, un PAR et un ROR. © L.Schmitz.

Les radars devaient tourner de concert avec une grande précision. Ici, un PAR et un ROR. © L.Schmitz.

The radars revolutions had to be synchronized together with a great precision.

Here a PAR (left) and a ROR. © L.Schmitz.

The obsession of every BCO was the ORE: ‘Operational Readiness Evaluation’. A team of evaluators (nationals or NATO) came

at the gate of the site and commanded ‘Go to Blazing Skies’. Once on alert, which could not last more than twenty minutes, the

evaluators checked whether all the equipment operated according to the criteria established by NATO. The ORE was qualified by

a score ‘Excellent’, ‘Satisfactory’, ‘Unsatisfactory’ or ‘Marginal’. Watch out if you got one of the last two notes! That's

exactly what happened to me during my first ORE... I had checked the alignment of the radars, which had to revolve synchronized.

This procedure had to be accurate to 10 ‘thousands’ near or less than one angle degree. However, the evaluator had measured a

gap of 25 ‘thousands’ on the console of the CWAR. This would not have prevented the battery to shoot down enemy planes, but hey,

these were the rules. The problem was that I was sure to have not made a mistake: my alignment was just pin-point perfect!

Then the evaluator asked me with a smile: "Was the door open this morning?” I looked at him bewildered. What was the relation

with the alignment of the radars??? The officer then disconnected the huge air conditioner which was hanging outside the BCC

and proceeded to a new control. This time, there was not even the slightest misalignment! The air conditioner was used to cool

the electronics and worked continuously excepted when the door was open... He explained that during the alert, the power

supply was switched from main current to diesel generator power. The current provided by the latter mean was less stable and

when the air conditioner was switched on, the voltage dropped slightly, but enough to alter the calibration of the electronics.

This phenomenon did not occur at the artillery school where the power was never supplied by generators. During the alignment

procedure, we had not only to use the power generators, but also connect the air conditioner, and remember to close the door...

A few years later, it was my turn to fail a rookie who committed the same mistake...

|

The Hawk batteries < Part 1 < Part 2 > Part 4 > Part 5 |

|

Plan du site - Sitemap |  |